Translucent Plastic Parts

Sheet Metal Parts

Night Lamp Products

Fruit Blender Products

Prototyping

CNC machining

CNC machining

For a small quantity custom metal and plastic parts, CNC Machining is the best cost-effective precision machining process. We can help you save the machining cost and increase your competitive edge with CNC machining. We are committed to provide you best machined products and services at most competitive prices. You can come to us for Custom CNC Machining, CNC Milling, CNC Turning and Precision CNC Machining.

CNC machining material:

Plastic: ABS, PP, PMMA, PC, Nylon, POM and so on.

Metal: Aluminum, Steel, Copper and so on.

3D Printing

3D printing is an additive manufacturing process that works best for functional prototypes, complex designs, reducing multipart assemblies and end-use applications. We provide SLA prototypes with a variety of plastic materials. Our strict quality control system and sophisticated equipment create high quality parts every single time.

3D printing is an additive manufacturing process that works best for functional prototypes, complex designs, reducing multipart assemblies and end-use applications. We provide SLA prototypes with a variety of plastic materials. Our strict quality control system and sophisticated equipment create high quality parts every single time.

Plastic Injection Molding

Plastic Injection Molding

In a fast-paced market, it is critical for a company to get new custom products into the market quickly. In most of the cases, it could be just a market-testing product with a small volume. But the plastic parts still need to be customized by injection molding to achieve the specified material, tolerance, finish, function and performance. Traditionally, a hardened steel injection mold would requires a very high investment before you get a piece of sample, and it usually take 8-12 weeks to complete, which are unacceptable for a new product developing at the earliest phase.

We need a solution to reduce the cost of the molds and shorten the lead-time for companies to launch new custom plastic products. Rapid tooling is what you are looking for, which means low cost, quick turn around and on budget.

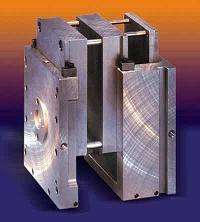

Like the hardened steel production molds, rapid tooling start with CAD design, and then CNC, EDM, wire cut, polish, etc. To achieve cost effective and a short lead time, we often use MUD mold base instead of customized mold base, use hand loaded inserts instead of sliders and lifters in rapid tooling. For the tool material, we use soft steel or aluminium instead of hardened steel, which make the processing easier and faster. The plastic parts’ quality from rapid tooling is almost as good as the one from harden steel production mold. And that, rapid tooling can save significant cost and time compare to hardened steel production mold.

MUD mold base

Conveyor belt for mass production

Multi-cavities hot runner tool for mass production

Low-Volume mold

Tool life: 50-10,000 shots.

Tool material: Aluminium or S50C steel

Tool lead time: 1-3 weeks for general tooling

Medium-Volume mold

Tool life: 10,000-100,000 shots

Tool material: P20 steel or 738H

Tool lead time: 2-4 weeks for general tooling

Large-Volume mold and Mass production

Tool life: 100,000-1000,000 shots.

Tool material: NAK80 or S136

Tool lead time: 4-6 weeks for general tooling

When the production quantity is larger than 100,000 shots, a hardened steel production mold will be needed.

We use NAK80 or S136 as tool material to achieve a long tool life.

We use good cooling system to reduce the cycle time.

We use multi-cavities tools to meet the large volume capacity and reduce the cost.

We often use hot tip gate, sub gate, hook gate and other automatic cutting gate to reduce labor cost.

We have mechanical arms and conveyor belt set on our Injection Machines to help mould the parts automatically and efficiently.

So for mass production, we can build a high quality hardened steel mold and produce the parts for you at a lower cost.

Stamping

Stamping tool

Stamping is one processing method for sheet metal. In this method, a metal die needs to be provided. Place a metal plate in the die and apply pressure, then the sheet metal part will be formed in the die. Once the die has been created, large quantities of components can be created using the same die.

Finishing Service

Flatbed printing

When applying the surface finish to the parts, the parts will be vivid and look more comfortable. We can provide many different surface finishing services to our customer. The finish can be formed directly from the tooling, such as polishing and texturing. And the finish can be achieved by post processing, such as glossy painting, matte painting, anodizing, electroplating, pad printing, flatbed printing and labeling.

Simple assembly

Ultrasonic welding

We can provide simple assembly service to our customer. We can do ultrasonic welding, heat staking, assembling parts with screws, etc. Our intention is providing a full set of parts with function to our customer. So that we can provide a better service to our customers.

Design in service

We prefer to provide tooling and molding solutions during the projects development and design Stage for you. Because it will make the projects move on smoothly and shorten the lead time. For example, thin walls are hard to fill and thick walls will cause sink marks easily, we can suggest the best thickness for the parts. To achieve the same function, we can suggest a simple design to reduce the tooling cost. We can provide suggestions on over-molding structure to improve the adhesion. We can provide solutions to avoid or reduce the cosmetic issue, like injection mark, weld line and warpage.

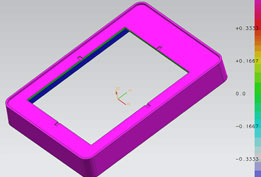

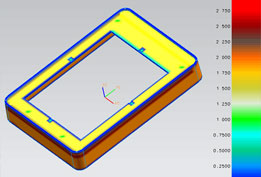

Walls thickness analysis