In producing plastic parts, nothing is better than plastic injection molding as a production method. It has even more advantages over other means of plastic molding because the process is less complicated but more reliable. It has the versatility that intricate engineering designs demand and the efficiency in terms of cost that many companies desire to keep their bottom line healthy.

Here are the reasons why you should choose plastic injection molding over other manufacturing methods.

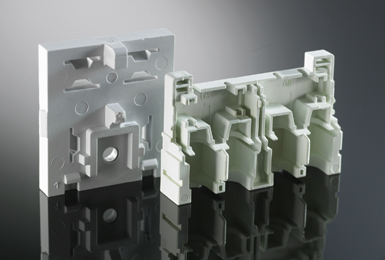

plastic injection molding products, *picture from boymachines.com

Highly Efficient and Faster Production

There are many reasons why plastic injection molding the best option for many companies as the most popular and effective form of injection molding. One of the reasons is because the process is the fastest when you compare them with other manufacturing means. It is also cost-effective and more efficient and therefore, has a higher production output. The speed of production, of course, depends on the complexity of the design and the specification of the mold. But cycle time is generally within the range of 15-200 seconds.

These short period in between cycles allows plastic injection molding to produce more molds in a short amount of time, increasing both the sales and the profit margins. The high production output makes this method more efficient and effective.

Can Accommodate Complicated Designs

Because injection mold is exposed to high pressure, the plastic inside the patterns is pressed and pushed harder into the walls. Compared to other molding process, only plastic injection model can incorporate all the details into the part. This means that there is no limitation to how much details should be in the design.

Another significant contribution of high pressure to the process is plastic molding can manufacture intricate and elaborate details with spending too much. Using injection molding can accommodate intricate designs while keeping the manufacturing process at low cost.

Enhanced Strength

Strength is one of the factors that you must consider when planning the production of molded parts via plastic injection. The designer must know if the components must be flexible or rigid so that they can adjust accordingly. If the designer knows the purpose of the part and environment where it will be used, they can specify the stability and strength the product requires.

Plastic injection molding can have a perfect balance that they need. Not only is the option for the type of resin to use, it is also possible to add fillers in the molds. The fillers can lessen the density of the material and help in adding stability and strength to the product.

It Offers Flexibility on the Choices of Colors and Materials

In manufacturing parts, there are two essential elements that you need, the eight color and material. If both are present, then there is no limitation to the design possibilities. There are many advances in polymers during recent times. This is also the leading cause of the development of a wide range of resins to choose from. Working with an advanced injection molding company that has experience with many kinds of resins and how to use them, the final part will have excellent results.

Another advantage when plastic injection molding is employed for manufacturing parts is it can simultaneously use different kinds of plastic using co-injection molding. In selecting the right plastic, the following important variable should be on the checklist: tensile strength, impact strength, elasticity, water absorption, and heat deflection.

With the use of different coloring systems, plastics can have different colors with their own benefits, properties, and drawbacks. Plastics can also use different coloring techniques like masterbatches, liquid color, and pre-colored resins.

Reduced Waste

Companies are now going green as they signify their commitment to sustainability, quality, and safety. Plastic is on top of the list of materials that are gaining less popularity. However, when using plastic injection molding, the excess plastic can be recycled. There are state-of-the-art types of machinery that can assist in minimizing waste, packaging, and transportation.

The Automation Process Lowers Manufacturing Costs

The labor cost is low in plastic injection molding as compared to other molding processes. It can produce the parts required at a faster speed resulting in a higher output rate. A typical plastic molding equipment is self-gating and operates on an automatic tool. It also keeps the operations streamlined and runs with minimal supervision.

In automation, the process is often performed by robotics and machines, and the operator can solely control and manage it. It also helps lessen the manufacturing and labor costs. These can result in a lower cost of manufacturing a product for the customer. Automation is also what makes precise and accurate molds.

The Bottom Line

Using the plastic injection molding process ensures that the finished product does not require any further work after its production. This is because the parts ejected from the molds already have a polished appearance.