CNC machining is not a new technology, but 3D printing is. Through the years, 3D printed objects have increased popularity amongst the technology aficionados and greenhorns. This is because this technology has a lot to offer and is becoming widely popular in the production environment. However, this does not mean that CNC machining is fading in the background. This article explores the strengths of CNC machining and 3D printing and how their importance in the manufacturing process.

The Similarities between CNC Machining and 3D Printing

Both CNC machining and 3D Printing or additive manufacturing are computer-controlled processes to produce something out of a given material, and both of them are machines that are at the front of manufacturing technology that is safe and efficient.

They are particularly useful for engineers and machinists who want to build a prototype, a part of a bigger project or a customized product. All the machine need is a design and leaves your worries about human error because the machine is fully automated. Although, there is no one hundred percent assurance that issues may arise. What is reassuring is that both processes have more consistency and the chance of injury is less.

The Difference between CNC Machining and 3D Printing

CNC machining is a lot older than 3D printing and has established a strong following in the manufacturing industry. 3D printing was introduced in 1986, is relatively new, and has become more versatile and accessible. It can help in prototyping, but it is not made as a replacement for CNC machining.

Additive Compared to Subtractive Manufacturing

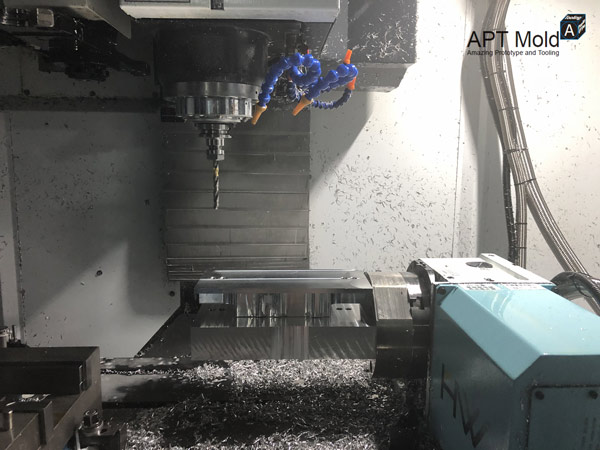

The major difference between a CNC machine and a 3D printer is their different processes. In CNC machining, a machine is usually fed with a big chunk of material where it is subtracted to produce the desired product.

A 3D printer is an additive process, meaning, a part is built manufactured by addition of materials in layers one after the other.

Light and Heavy Materials

The matter that differentiates CNC machines from 3D printers is that it offers creative freedom and the flexibility in materials. The materials we are talking about are as varied as metal alloys like steel, brass, and aluminum, super alloys like Monel, softwoods, hardwoods, thermoplastics, and acrylics.

A 3D printer used materials that are softer in nature like thermoplastics and resins, and unlike CNC machines, individual printers are specific to one material alone.

Hand Finishing and Quality Finishing

CNC machines are equipped with tools that make secondary finishing easy. On the other hand, the 3D printer, which is quite in demand for manufacturing custom pieces, is becoming the preferred choice. The products from 3D printers require hand finishing after they are produced. This is the reason why they are in demand for a specific market. CNC machining, on the other hand, is ideal for volume production that needs quality finishing.

According to the experts, 3D printers are not out there to replace CNC machines. It is made to improve the certain aspects of manufacturing and not the whole market, CNC machining still covers the bigger part of the production.