A prototype mold is used for many industrial applications like bridge tooling, pilot runs, production of low-volume parts, and prototyping molds for various functions. Injection molding is the preferred method used in a prototype mold. It is suitable for a wide array of colors and material formulations. The important advantage of such prototype mold is a fast turnaround, high repeatability, and material versatility. The equipment used to manufacture such moldings are mostly cost-efficient tools.

The process involved in injection molding technology

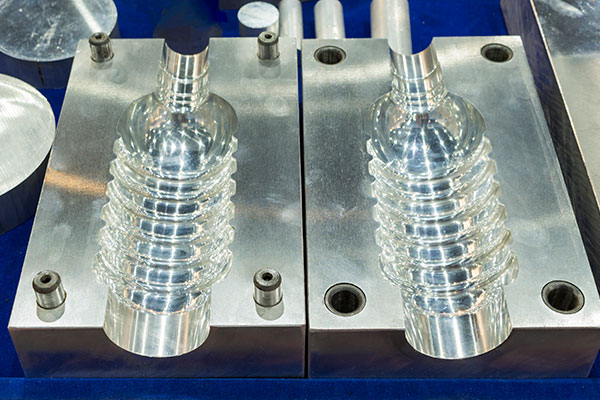

The injection molding process uses ceramic, steel, or aluminum molds for shape formation. It does not involve heating or cooling lines that actually means the time per cycle is quite long. Such a long duration helps in observing the fill pressure and quality of the components. The process starts by loading of resin pellets into the barrel. They will get melted, pressed, and then injected. The mold’s runner structure will be filled with the injected resin pellets. Hot resin will be shot into the mold chamber by means of the gates, where the part gets molded. There are ejector pins inside the mold barrel that helps in removal of the structure from the mold. The prototype mold falls into a loading pin. After the run gets completed, the molded parts are shipped are transferred to the clients shortly.

Injection molding types

- Over molding: It is a process which involves two layers. A thermoplastic elastomer or a rubber based liquid silicone is molded over some other components. For injection, the base component portion is first placed and then around the inserted part, hot molding is The result forms the finished product.

- High-speed injection molding: They can be operated in automatic modes. It consumes low power and installation is very simple. The injection molding machine is highly efficient and has durable finishing.

- Double shot molding: It involves the process of molding plastic that surrounds a preformed metal. It is used for manufacturing keyboards and other such commodities.

- Insert molding: A pre-placed insert will be available through which plastic is inserted into a mold. The resultant prototype mold will be a single plastic piece with an insert. It is used in many industries and is used as insert-molded couplings, filters, and electrical components.

- Two shot molding with rotating platen: It involves the innovative manufacturing process of double injection technique. These complicated molded parts are produced by two various materials.

- Conventional molding from 75 tons to 500 tons: It is made from high-quality raw material and use of modern technologies. It is of premium quality, highly durable, and functions with great efficiency.

injection mold, *picture from valenciaplastics.com

Limitations in manufacturing prototype molds

Before considering the above injection prototype molds, the following limitations must be kept in minds

- Stronger mold: In order to withstand the injection molding process, the mold must be of stronger quality. If the material of the prototype mold is not strong enough, then it might not survive until the end. The machines that are being clamped are usually measured by pounds per square. In addition to that, the mold must withstand temperatures of hot plastic while molding.

- It should be smooth too: In addition to the strength, it also must be smooth enough to eject the plastic part without any mess. In order to make the ejection process easy, traditional machine molds are smoothed and polished. But in case of rapid tooling, the materials are layered and it might not be smooth enough. It means that there is additional work to be done in order to make the molds smoother.

- Tolerance:The molds manufactured must be of higher tolerance. The level of the tolerance must be ‘+/- 0.001’. Depending on the type of material used, undergoing the process with this tolerance might be difficult.

Most common methods of prototype rapid tooling methods

Prototype molds can also be available in

- 3D printing: The prototype molds by this process can be done extremely quickly. They are pretty inexpensive and you can get the necessary geometry of the product.

- Direct metal laser sintering: Sintering is the process of creating a plastic injection mold by bringing together solvents with fusing metal particles. It helps in cooling of the mold quickly and helps in molding shapes of various geometries.

- Traditional machining: With the help of rapid tooling, traditional machine moldings of aluminium and copper became easier. The only limitation of using traditional machines is that it cannot make products of desired geometries.

Most injection molding services can be obtained by placing a quote. If the company accepts your bid, you can get the products shipped within 10 – 12 days. Different prototype molds are being manufactured by multiple industries. Many companies even export and import their products to different parts of the world.