APT Mold Blog

Know more about the most advanced technical information in manufacturing industry, and other funny things.What Is Rapid Tooling and Its Benefits

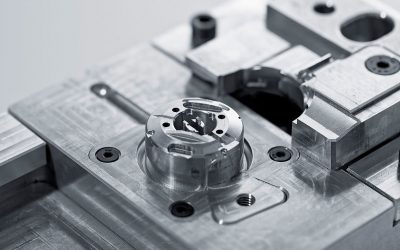

A combination of rapid prototyping technique along with the conventional tooling procedure results in rapid tooling. It helps in producing molds more quickly. The process is also used in preparing various parts of a functional CAD data model in a relatively less time...

Reasons Why You Should Consider Rapid Tooling

Rapid tooling is a combination of conventional tooling methods and rapid prototyping techniques to create molds faster. With this process, it cuts the time and the cost of producing a mold, ensuring that the product gets into production quicker and reach the market...

Rapid Tooling technology – The Importance

Rapid tooling can be understood as the combination of conventional tooling practices and modern rapid prototyping techniques. This combination can result in the building of the mold quickly and with high perfection. This is one of the most popular processes today...

Rapid Tooling – A Comprehensive Guide

Rapid tooling is the procedure which finally results in combining conventional tool practices along with rapid prototyping technique. This produces a mold quite quickly or some parts of a functional model from the CAD data in a short time and at a relatively low cost...

Rapid Tooling: Its Processes, Advantages, and Applications

If you want to market your product faster, you will need rapid prototyping to make the parts readily available for testing. There are many innovations in the manufacturing industry in recent years. And among them are the various rapid prototyping techniques that can...

Basic Knowledge You Need to Know About Rapid Tooling as an Entrepreneur

Rapid tooling was a pretty new manufacturing procedure that was created with the sole purpose of creating small production runs of certain items. The techniques proved to be so effective that many workshops tweaked the procedures to suit their own needs. Many...

A Quick Revision to the Types of Rapid Tooling Used To Create Prototypes

The basic definition of rapid tooling is the creation of a molding cast with very short notice. The science used for this technology was created back in the ’90s. A team of engineers in the USA was looking to optimize the procedures to create a mold since the time...

This is How Choosing the Right Plastic Injection Molding Manufacturer Gets You a Better Product

The dynamics of business can be daunting for most on a good and downright scary for anyone who doesn’t have the stones to be competitive. Not only you need to have a great idea, but you also need to be able to deliver your product better and faster than most of your...

Let’s Talk About Design Manufacturing for Plastic Injection Molding Projects

When you are dealing with plastic injection molding projects, you have to put a great deal of thought into how your product will come to be. There is no single step that you can overlook for the hell of it. Manufacturing, as it’s conceived in these times, is one of...

Dealing With the Cooling Rate on Any Plastic Injection Molding Process

If you are wondering what does temperature has to do with plastic injection molding processes, you probably don’t know a lot about the topic. We are going to illustrate over the following lines a basic outline centered on the basics of cooling rates on manufacturing...