APT Mold Blog

Know more about the most advanced technical information in manufacturing industry, and other funny things.Why Having Second Thoughts About your Prototype can be a Good Thing

Let’s talk a moment about second thoughts. We have them all the time, and they are mostly these annoying second guesses that hold us back from doing something bold and daring. For the regular Joe, they are the conscience that keeps them safe behind the...

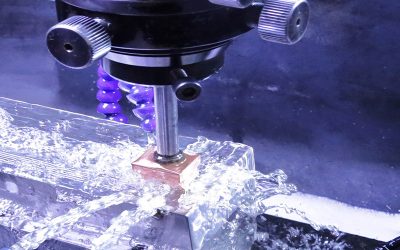

Multifunctional Milling Tools that can be Used on Your CNC Machine to Get Better Results

Our definition of multifunctional tools is pretty simple: it’s tooling capable of achieving more than a single function. It can help you save time, money and the annoying process of changing a tool to complete a task. In the field of CNC machining...

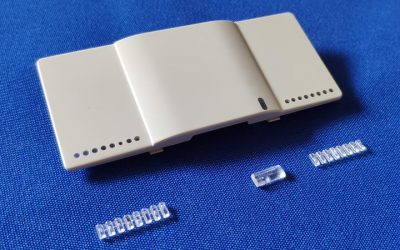

How Can Rapid Prototype Be Used in the Electronic Appliance Industry?

Manufacturing electronic devices are not exactly difficult with modern assembly lines, but having all the parts and pieces required to get these products ready, up and running requires that the big companies behind them are able to procure the production...

How to Use Chamfer Mills, Cutting Tools and Router Bits Properly

Just in the same way as scalpels are the precision tools of choice for surgeons, chamfer mills, cutters and router bits are the tools of choice for anyone in the CNC machining trade. They make possible the crafting and creation of parts using CNC machines....

The Basic Applications of Rapid Prototyping in Manufacturing

Rapid prototyping services have changed the manufacturing landscape since its introduction in the late 1980’s. Initially, the reason why it was developed is to support product development by creating a physical model that can validate the design faster at...

The Advantages and Disadvantages of Rapid Prototyping

In business, there are three things that matter to be successful – quality, price, and effectiveness. You need to have a good quality product for your customers to trust you and prefer your brand to the rest. Price is important in product delivery because...

How to Get Rid of Design Flaws on Your Product

The technology to build parts or products has improved by leaps and bounds in the last 20 years, more accurately since computer systems were added to the manufacturing process. Right now injection molding, CNC machining, and prototype molds are a rule of...

Pros and Cons of Outsourcing your Rapid Prototype Project

No one can discuss the efficiency of 3D printing procedures to create a prototype in 2018. For many rapid prototyping services building models by hand or crafting tooling has stopped being cost efficient since 3D printing works just as good, with more...

Main Differences Between Production Runs and Prototype Tooling

Troubleshooting and testing are some of the most critical stages when you are dealing with products development, most of the times the creative team behind a new design new to do multiple tests runs to approve the next stage of tooling or manufacturing....

How can Prototype Molds Help You Launch a Product?

When you are an entry level developer looking to create your first product that first thing you’ll notice is just how expensive injection molding can be when done correctly. If you are working with an integrated company, the cost of the budget will seem...