Did you know that most of your kitchen utensils are created using sheet metal manufacturing techniques? Many of the pots and pans you use every day are created using this technology. Kitchen sinks and container cans for the same space are created with this tech too. Sheet metal manufacturing is also used to produce automobile parts such as panels, gas tanks, and other sorted pieces of the vehicle. The process used to obtain their particular shape is named deep drawing process.

Deep drawing is probably one of the most popular manufacturing methods used to handle metal fabrications around the world. Many industries keep using this basic procedure to create concave shapes, recipients, and curved pieces. As you can guess, the basic of deep drawing has to do with radial configurations. The process is handled by a machine that punches metal sheets with circular comers and dies to achieve wider radius shapes.

When we handle deep drawing tasks, we need to make sure that the punch-die space is larger than the sheet of metal we intent to work with. If our work piece is thicker than our die, we won’t be able to make much of a dent on it. Deep drawing is mostly used to create round-shaped recipients and a few box-shaped structures. The process is called “deep drawing” because the drawn-out part of the finished piece has more depth than diameter.

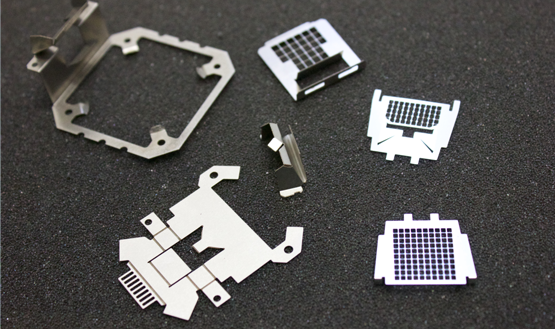

sheet metal components, *picture from masar-eg.com

Materials Used for Deep Drawing Tasks

Metals are the go-to choice in this regard. Deep drawing works great with sheet metal manufacturing methods that call for aluminum, brass, cold-roll steel, and stainless steel as well. Softer metals such as aluminum are easily transformed with this technique. This was especially useful back in the big world wars were soldiers needed to carry recipients for water or coffee. These days the same pieces are created by machines using less strength and with more chances to be durable.

The Mechanics Behind Deep Drawing

The working method to create pieces using deep drawing techniques calls for five stages. The main tool deep drawing is a punch as well as a die. The punch needs to be designed with the shape of the base at the bottom of the piece once the product is drawn. The die should have a hollow contour that matches the punch with precision. This will make easier every task by allowing a smooth hit on the workpiece to be retrieved.

Deep drawing requires progressive hits for some products to get done. These hits are supposed to stretch the sheet metal to make the radius of the piece bigger. This is also a way to save money on materials and a way to optimize each task. When a piece requires augmentation or reduction, the number of hits will vary a lot. A previous study should be done on the design phase to avoid wasting material or cracks in the sheets of metal.

The setup required to work any deep drawing task is pretty similar to a cutting job using metal sheets. You need a measured lateral distance among the edge of the punch and the die. Sheet metal manufacturing companies use mechanical and hydraulic presses for deep drawing products. Both machines are required depending on the type of order of the client or the size of the order. The following list includes the five stages of development we mentioned earlier:

· Punching the Metal Sheet

Deep drawing processes begin when the punch hits the metal sheet for the first time. Previous to the first hit, you need to place the sheet on the machine handling the task. You also need to make sure that the punch is in the right place, and the right pattern for fabrication has been programmed. Make sure that the equipment does not vibrate with a hit. That could harm the finished product.

· Bending the Sheet

There should be an initial application of force on the sheet. This first hit should bend the contour of the die cavity. As the bending process goes on, the strength applied on the sheet should never exceed the amount of pressure applied to the metal being pressed. That way, we can avoid wrinkles on the metal sheet.

· Straighten the Work

The next step is to increase the force applied to bend the sheet on the blank. By doing this, we will straighten out the metal without breaking it. During this procedure, we will sink the annular punch-die clearance. When we straighten out a metal sheet, we get shorter vertical walls. This is also a process that allows us to see how much we can actually extend metal sheets to get what we need.

· Friction and Compression

On this stage, the blank will flow following a radius pattern as friction works to do the rest. These frictional forces will act on the lower surface of the piece as well as the upper part of the die. Frictional forces will slowly decrease as the metal sheet moves along the surface of the die. After the friction passes, the blank will show compression, and it will shrink to a smaller size than the die.

· Releasing Tension

In the last stage of this sheet metal manufacturing technique, all of the stress of the piece is released. The blank has to fit in the die cavity creating a vertical wall. The remaining blank takes the shape of a small flange, and the new piece will be treated with uniaxial tension to be ejected.