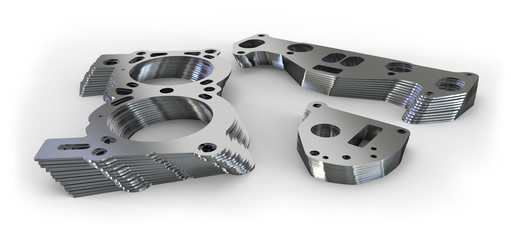

When the topic is rapid prototyping services, tolerance is probably one of the most critical parts of the design stage that has to be treated with precision and reassurance on the numbers available. It’s almost, and the success of the project depends on it. For starters let’s clear some ideas to get a better idea about why this is such a big deal. Tolerance is a planned deviation of the exact measurements or dimensions of a project. CAD files usually express tolerance numbers using the coded “+/- “for sizes expressed in millimeters. Project handlers’ need to have a pretty clear idea about the measures needed in critical areas of the product they are creating. High tolerance in the whole part is not exactly a good thing. Inflexion points are always preferable to prevent performance issues.

ISO Norms and Points of Tolerance

One of the real reasons for tolerance being such a necessary trait in every product comes from the ISO quality standards regulating the creation of parts that are used for practical purposes. The regulation numbered #2768-1 is the one that states all matters related to linear and angular dimensions as well as the radius and flatness that some surfaces should have. The norm also clearly says that the lowest tolerance that must be induced in any angular shape should be of 50 microns or 0.06 millimeters. For the untrained eye offering induced tolerance to anything that gets manufactured it’s a way to create a faulty product when it’s actually the contrary. Everything that is built with the precise tolerance is something that will perform in accordance with the designs with fully functional features and smooth seams.

sheet metal, *picture from standard-spring.com

Second-Hand Effects of Proper Tolerance

The other reason for induced tolerance on your products is because tight features are never good. Something that doesn’t let in anything will be impacted by temperatures pretty easy. An overtly-tight screw can rearrange the shape of any finished products if we are talking about an independent part. Lack of mobility and high exposure to vibrations will wear anything that solid pretty quick. The range of motion is needed to make sure that parts are able to fit or removed if necessary. A trade secret among most rapid prototyping services is also the fact that chasing such levels of perfection on any project means that they are bound to fail at some point, specifically during the performance stage. It’s also needed because even with the precision offered by most rapid prototyping hardware, there is still room for imperfections.

Why Tolerance Matters

Now with all this information in hand, you may have a different approach to that product that hasn’t been testing well despise the top-quality design. It’s not always a matter on the side of equipment when performance issues arise. Being flexible is a way to make sure things go smoothly. Following the directive #2768-1 from the ISO, regulations are a way to offer some reassurance to the engineers tasked with your project. It’s also important to pay attention to their warnings, most of the times they know what they are doing, even if the manufacturing company you chose is not handling the design of the products you are creating. The term “concession” for rapid prototyping services hardly means defeat, if often translate into improvement!