Laser CNC machines are one of the hottest trends in the world of crafts right now, this is one of the finest and more precise tools to create items that are not only beautiful but also functional. Chances are that you already know more than one entrepreneur using one of these tools to create laser-sculpted jewelry or scrapbook items. These laser cutters are considered very versatile because they are used to create home accessories, fixtures, and the occasional ornament. These machines own their popularity due to the fact that they are a more accurate replacement to cutters of all sorts. A drag knife has nothing on them and they certainly can handle nearly every surface you use them on.

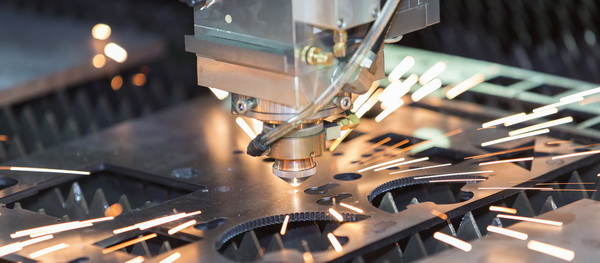

Laser Cutting * Picture from ametals.com

The Advantages of Using Laser Cutters

When compared with similar devices the results seem to stand out on the side of Laser Cutters, although they do have an industrial use, they are mostly a method preferred by enthusiasts and prototype designers right now since laser cutters can offer levels of details that any physical cutter can’t even hope to deliver. The creation of structures in 3D printing is certainly one of the greatest achievements of laser cutters: the combination of plugins to create box-shaped structures in specialized software has completely replaced the use of glued models. Casting out a personalized flat sculpt has also become a staple by many artists willing to bring portraits to life using the technology.

Considerations before Choosing a Laser Cutter

If you are leaning toward Laser Cutters for business reasons or just because you want to try your artistic expertise to create something with these devices there are some features you should look for. Take a peek at the following:

- Make sure it’s user-friendly, even if you know how to operate one. At some point, you will probably have to train someone else how to use it and this feature will work to your advantage.

- The printer should have its own designated software to handle your designs. If the machine doesn’t have one, make sure it’s compatible with one of the many programs available on the market to manage designs to the printer without issues.

- While it’s more expensive, make sure your laser cutter has air cooling laser tubes. This cooling system is much safer than anything liquid-based and prevents any hazards in the long run.

- If you are on a budget and you are choosing foreign brands, make sure to learn everything you can about the specs and save some money for additional modifications. Customizing a laser cutter is not as expensive as it seems but it will require for you to improve the ventilation of the device as well as the cooling system since these devices are prone to overheating.

Last but not least: always make sure that the laser focus can be adjusted both ways: automatically and manually, especially if you are doing custom work. You will need it for precision work!