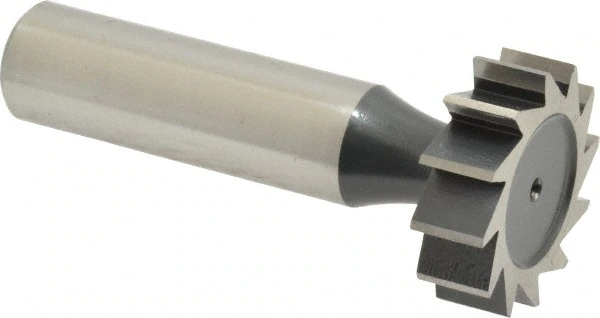

Keyseat cutters are a fixture on every workshop handling CNC machining jobs. The multiple angles of this mill make it an ideal tool to manage complex shapes and angles, even if most technicians use it on a slot side of the mill to get the best work out of it. Staggered Tooth Keyseats cutters can be used alternating directions, so it’s suited for both left-handed cutters and right ones. As you can tell by now, it beats using the traditional cutter since this one can go beyond simple perforation. The unique geometry of Keyseat cutter increases the feed rates on the slots of any CNC machine, and it also provides a better-finished product.

keyseats, *picutre from cnccookbook.com

If you are still wondering about what Keyseat cutters can give you, let’s take a look at the list of benefits most professionals have gathered since they were introduced to the market:

Improved Fee Rates

As we stated previously, the geometry of Keyseat cutters allow many benefits when you are working with certain mills. When it comes to getting rid of chipping, the staggered form of the keyseat cutter drives away these parties with wind-like propelling and the combination of left/right handed shear flutes. The tips used on Keyseat cutters alternate between up-cuts and down-cuts that minimize the presence of chipping to a powder-like substance while getting the job done quicker than usual.

Versatility

The alternative mechanism that handles the drive of the left/right handled flutes give the cutter an increased rate of performance and an extended life period because the piece receives constant relieve on both sides of the tip whenever is used. What does this mean for your CNC machining projects? Well for once, this feature cut costs on tooling by using a single mill that can be indexed axially to expand or contract the slots is working on no matter the dimensions requested. No longer will you need to change the tooling on the mill to get a complex job done!

Better Finishes

Keyseat cutters have a lot of flutes to help give your project the right angle and to reduce the need to cut the plaques of material you are working with. The decreasing production of chipping can be topped with a near to non-existent waste of your raw materials. The flutes are also designed to make vibrations or any chatter that can affect the finished product. The strength of the mill will not be an issue either since the cutter allows for increased stability. In other words, the finished product should be smooth and beautiful to look at.

Keyseat Cutters: A Truly Improved Method of Tooling?

We can safely say that keyseat cutters are a rather efficient method of manufacturing, but it still requires more exploration and experimentation. So far the tips have been used to create some of the most sophisticated parts using round shapes, but developers are pretty sure there is room for more. The multiple sizes of these tips also make them very reliable on all types of work. The current sizes offered range from 1/8” to 5/8” with various degrees of length for deep milling. What does this mean for the future? It all depends on the human imagination.