Low-Volume Manufacturing Services

Low-volume Manufacturing

Quick parts Manufacturing

50-10000 parts

Low-volume & Quick parts manufacturing is the option to conduct design and functional testing of injection molded parts and metal parts, The quantities of finished parts ranging from 50-10,000 parts.

If you only need a few parts, you may consider one of our prototype services

What Is Low-Volume & Quick parts Manufacturing?

Low volume & Quick parts manufacturing is a customized service offering production-quality parts but in volumes usually limited to 10,000 pieces or fewer, it is one of the world’s most popular manufacturing processes.

Low volume & Quick parts manufacturing offer the advantages-fast production of complex parts and the ability to make frequent revisions.

Benefits Of Low-Volume & Quick parts Manufacturing

How can low-volume & Quick parts manufacturing help you and your business? Here are some of the benefits:

- Create a bridge between a few prototypes and mass production.

- Average lead time savings.

- Average cost savings.

- Spec resins for true functional evaluation.

- Early assessment of part performance and tool design rapid validations.

- Early confirmation of thermoplastic selection prior to mass production.

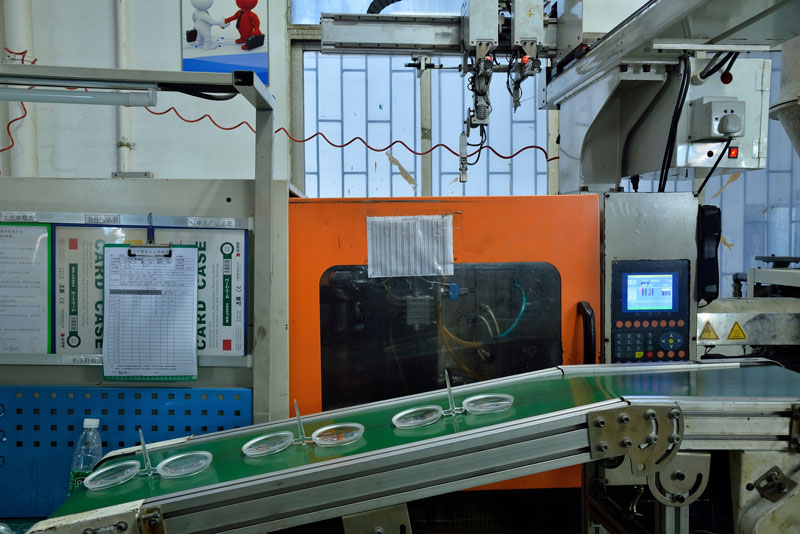

Plastic Injection Molding

Plastic injection molding is a process that utilize the pressure powered by injection machine to inject the hot melted plastics into the cavity, cooling and forming the parts.

Why using plastic injection molding? you would be benefit from the below items:

*High production efficiency, good for mass production for high quantity, medium quantity, low quantity, also your required quantity of plastic manufacturing.

*Material saving, high material usage, especially in hot runner system.

*Manufacture the complex parts that the other process may not produce, slide, lifter, hand load insert will be good for your complicated mechanical structure. interchangeable insert will help you save cost.

*Manufacture the part in high dimension requirement, dimension stable.

*Use automated molding systems run day and night, that will help you shorten the lead time of production to meet your large quantity and urgent use.

*Plastic injection molding is good for cost saving, especially the multi-cavity tooling.

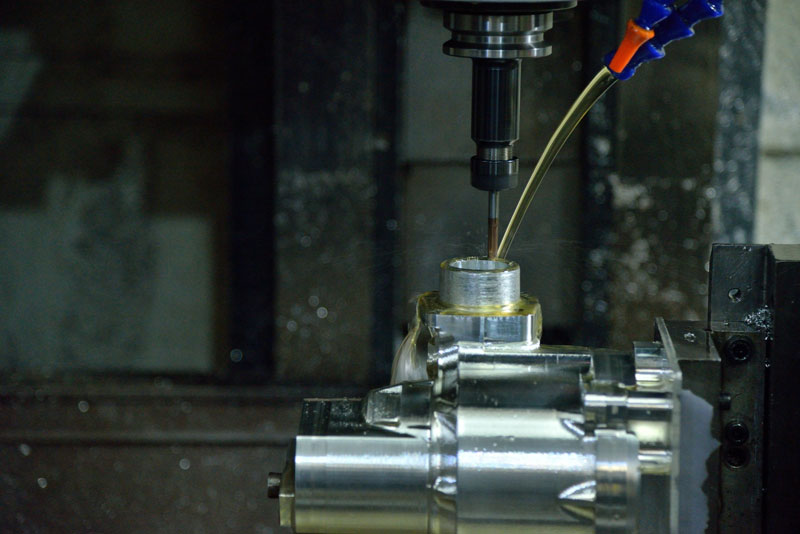

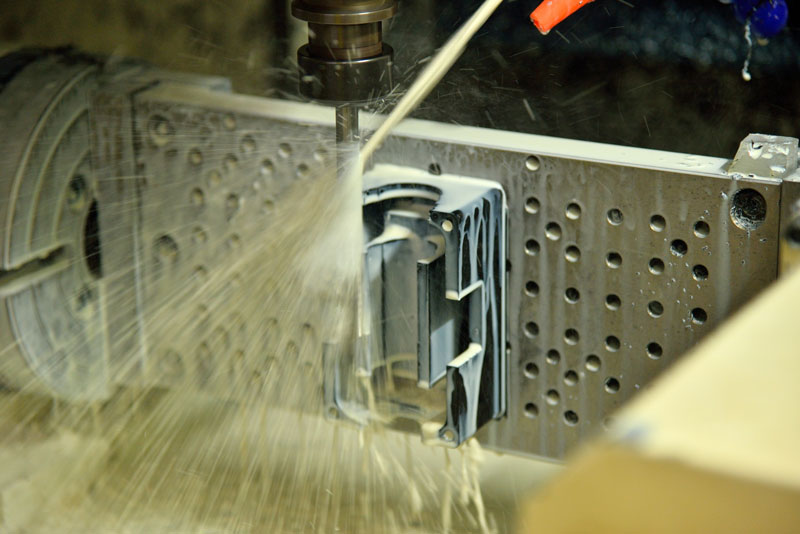

CNC Machining

CNC milling in a wide range of plastic and metal material

Plastics: ABS, Polypropylene, PMMA ( like Plexiglas® acrylic), PC (polycarbonate, Lexan®), Nylon, POM (Delrin® acetal), and more. Contact us about other possibilities.

Metals: Aluminum, Low-Carbon Steel, Stainless Steel, Brass, Copper, and more. Contact us about other possibilities.

CNC Machining Metal Parts

CNC Machining Plastics Parts

Technical Support

The support from APT team will help you shorten the lead time and cost saving in new product development. We will support your project design for manufacturing.

Innovative Ideas

We have innovative ideas based on design. Our manufacturing experience will help you trouble shooting and turn your idea into reality, get things done.

Advanced Technology

Our rapid prototyping technology in Computer Aided Design(CAD) and Computer Aided Manufacturing(CAM) also with experienced technician will make the parts in high quality.

Fast Response

We keep a close eyes on your every project, you will usually receive our quotation and get a reply for project within 24 hours.

What is Your Next Step?

This will guide you through our very simple quote submission process. We are excited for the chance to earn your business!